Why ZAIDAN PEBs ?

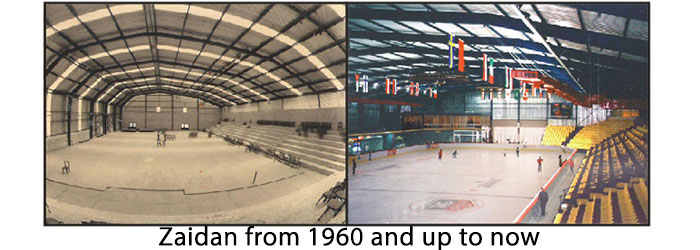

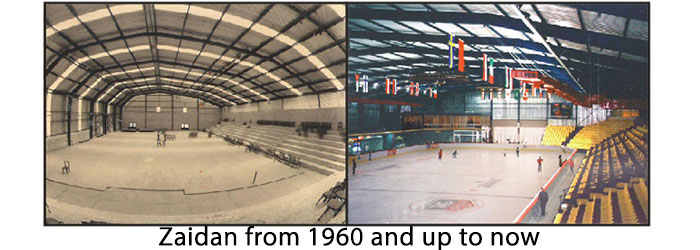

Mainly because of Zaidan's extensive experience in steel buildings. Zaidan is in the market since 1962 & has performed all types of steel projects all over the MENA countries. .

Furthermore, while Zaidan is small

enough to listen to your concerns and give you individualized attention, it is big enough for the detailed study & fast execution of large projects (40 Tons per day).

1- Quality

Design is in accordance to the latest codes. It is carried out by professional engineers specialized in steel buildings. Material's history & mill can be traced. Material undergoes a rigorous testing & approval process. Fabrication is as per ISO 9001 with a proven quality plan. Zaidan steel structures are shop-welded for field bolting.2- Cost

Zaidan puts steel where steel needs to be put. Extensive use of tapered sections ensures that steel is placed where moments are largest, hence preventing the need for clients to pay for steel which they don't really need. Tested high strength steel permits smaller sections hence more economy in manufacturing and erection. These economies are passed on to the user.3- Schedule

For most standard structures, Zaidan delivers within six weeks after approval plan's signature.4- Service

Client deals with one party for design and fabrication. Zaidan is also responsible for consultant approvals. Furthermore, at Zaidan, client deals only with one CC, (Customer Consultant) from beginning to end, through contract signature, approval plan preparation, consultant discussions (if applicable), production and shipment follow up. This trained CC, "one stop shop" facilitates the clients' life. Once the offer is signed, client gets an approval plan where all that will be delivered is clearly shown, thus avoiding potential misunderstandings.